IoT ensures maximum uptime for essential machines and assets

Improve productivity and efficiency by tackling maintenance issues before they occur.

What is predictive maintenance?

IoT predictive maintenance involves managing the upkeep of machines or equipment by identifying a fault before it happens. On the other hand, reactive maintenance involves fixing a component only after it has broken down. Predictive maintenance uses IoT technology to study the system in question, in real time and forecast when and how a malfunction might occur. This is done by collecting data around the machine’s maturity and operating condition and uses software to analyse that data to create performance reports. During this process, any potential glitches and breakdowns can be spotted and mitigated proactively.

There are several key elements to predictive maintenance with IoT technology being one of these critical pieces. Connected sensors capture information about the machine’s wellbeing and business systems then make sense of it. Examples of connected sensors include vibration analysis, oil measurement, thermal imaging, and equipment observation.

The growth of predictive maintenance

Unplanned downtime resulting from equipment breakdowns is the number one enemy of operational efficiency. This type of operational stop lasts longest and incurs the most expense for operators.

Predictive maintenance is based on the collection, management, and intelligent use of data. IoT-driven predictive maintenance is ideal for tackling unplanned downtime. Different operational parameters like temperature, motor vibration and currents can be analysed to pinpoint common symptoms preceding historical failures. This knowledge enables operators to predict future breakdowns and service equipment before they happen, thereby reducing engineer time to repair and operational downtime.

Adapting a predictive maintenance strategy requires an understanding of how and why asset failure occurs and identifying the warning signs of potential problems or failure. Predictive maintenance also provides the means to improve productivity, product quality and overall effectiveness of manufacturing environments.

Benefits of predictive maintenance include:

- Reduction of unscheduled equipment downtime caused by equipment or system failure

- Increased production capacity

- Increased labour utilisation

- Reduced operational and maintenance costs

- Increased equipment lifespan.

Predictive maintenance programs have been shown to lead to a tenfold increase in ROI, a 25%-30% reduction in maintenance costs, a 70%-75% decrease of breakdowns and a 35%-45% reduction in downtime.

The role of cellular connectivity in predictive maintenance

Global network coverage

For global IoT deployments, cellular connectivity is widely considered the most logical and reliable connection option. There is no need to build new infrastructure nor add additional network gateways to support remote deployments. Connectivity is via the cell towers that are already in place. The already tried and tested infrastructure, also provides the added benefit of cellular roaming. For solutions that may either be deployed to an unknown spot in the world or move frequently between regions, a cellular provider with multiple mobile network operators (MNOs) would be a sensible option.

Low Power Wide Area Network

As the title implies, Low Power Wide Area Network (LPWAN) technologies use very low power to provide long-range cellular connectivity. LPWAN technologies use a small portion of the mature and reliable LTE bandwidth to provide connectivity that’s ideally suited to devices that rely on battery technology to function.

Historically, a significant limitation for cellular adoption has been power consumption and battery life (or lack of!). LPWAN protocols like LTE-M and NB-IoT make it possible for cellular IoT modules to not only save power when not in use, but to also transmit relatively small amounts of data with minimal power usage.

Both LTE-M and NB-IoT are designed to offer years of operation from a battery-driven power source. Since data throughput is limited (but often more than enough for relaying sensor data), simpler signal modulation schemes and less complex radio modems are needed, leading to diminished power requirements. Advances in wake/sleep modes on modern hardware only contribute to these benefits.

Security

Cyber security risks are a reality. It is essential to keep the gateway secure and create private connections to the Cloud. On-SIM technology and mobile core network services, resolves IoT device identity issues, enables dynamic scalability and provides defence against spoofing of IoT devices, ransomware events and unauthorised device access to network and Cloud services.

Since cellular networks use SIM cards for authentication, it’s exceedingly difficult to spoof the identity of a device. SIMs can be pre-provisioned to securely communicate with Cloud Services. Compare this to Wi-Fi: When connected to a public Wi-Fi network, devices are sharing the connection with all other devices on the network. If any individual device has a security concern, all devices are at-risk. Cellular keeps every device separate from every other device, ensuring the security of the data being transmitted.

IoT connectivity solutions for any sector

Our IoT solutions enable precision farming, optimise resources and improve yields through data-driven decisions for smart, sustainable operations.

Our IoT solutions offer remote control, real-time monitoring and automation of wearables, home appliances and digital assets for enhanced convenience and security.

Our IoT solutions enable predictive maintenance, optimise distribution and support smart grids, enhancing reliability and sustainability whilst reducing costs.

Our IoT solutions offer critical data for environmental protection, regulatory compliance and sustainable resource management, fostering a healthier ecosystem.

Our IoT solutions enable real-time patient data, predictive maintenance of smart devices and better treatment outcomes for personalised healthcare.

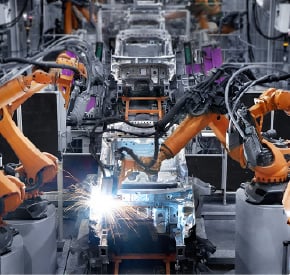

Our IoT solutions improve efficiency, reduce downtime and enhance quality control, transforming operations into smart manufacturing processes.

Our IoT solutions optimise supply chains, reduce costs and improve delivery accuracy for better reliability and customer satisfaction.

Improve service delivery and operational efficiency with smart infrastructure, real-time data and automation for a safer, sustainable community.

Our IoT solutions optimise stock management, support sales strategies and provide a seamless, personalised shopping experiences.

Our IoT solutions offer comprehensive coverage, improve incident response and enable proactive threat detection, protecting people and assets.

Our IoT solutions optimise energy use, enhance occupant experience and reduce costs for sustainable, intelligent building environments.

Our IoT solutions enable local authorities to improve urban living, through real-time analytics, connected infrastructure and automated services.

Our IoT solutions reduce downtime, improve delivery services and boost customer satisfaction driving innovation and sustainability in transportation.